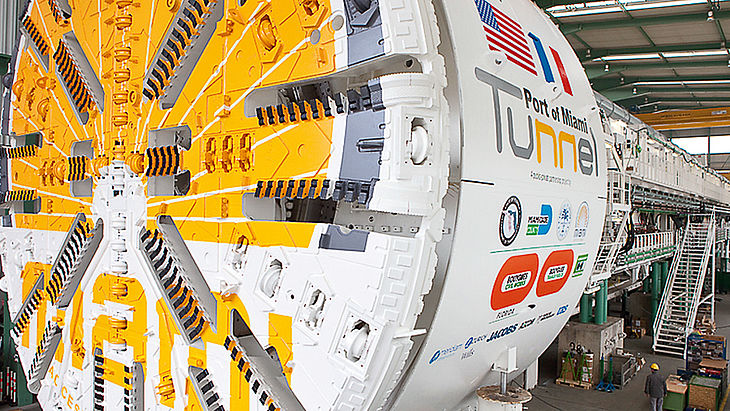

National Fire Protection was proud to be part of the construction of the Port of Miami Tunnel project.

The Challenge: Create a deluge fire suppression system for twin tunnels that are each 4,200 feet long, 43 feet in diameter, and 120 feet below the Miami seaport.

Tunnel fire systems present unique problems. Space is limited, and curved tunnel walls make standard cabinet designs un-workable. Air currents can push heat away from the fire’s source, paternally activating sprinklers that can’t reach the fire. The fire can even be a moving target on a burning vehicle. And high gallon per minute flow requirements make valve specification and design far from routine.

To address these challenges, the Port of Miami Tunnel Project turned to

National Fire Protection, LLC head-quartered in Maryland as its contractor.

With successfully completed projects that include the Pentagon, Dulles International Airport, the US Coast Guard Headquarters, Marlins Ballpark, and Miami International Airport, NFP was well suited for a job of this magnitude.

After NFP’s initial review of system and component specifications, they recognized a number of roadblocks:

1) Their initial valve selection could not supply the required flow rate

2) Friction losses were very high

3) Ferrous metal components did not meet the D.O.T. requirement for 100% U.S. sourced materials.

NFP brought these and other design criteria to Viking. With a plywood mock-up as a starting point, Viking was able to specify a 100% US-sourced valve rated for the required 1,100 gal/minute flow rate, design a contoured control cabinet that fit perfectly within the curvature of the tunnel wall, and develop a total package assembly/test/shipping process that delivers a “plug and play” system to the construction site. A 3D model was delivered within 2 weeks of Viking’s engagement, and the next 6 months were spent working with NFP to refine the details so that the design met every POMT performance requirement.

A visual monitoring system with immediate on/off actuation was required to insure that system controllers could send water to any zone in a matter of seconds. Zones can also be actuated from their individual cabinets, which are not locked and are clearly marked with operating instructions. Cabinet doors are equipped with alarms that alert operators when the cabinets are accessed.

Among the Viking system’s unique features:

• The system is electrically operated. An impulse valve is utilized in lieu of a standard normally closed solenoid valve, so the system stays latched in its last operating state. If for whatever reason wiring is breached during an activation, the system will continue to operate.

• All components, including the fasteners, are sourced in the United States, and the entire system is manufactured in Viking’s plant in Hastings, Michigan. Domestic sourcing allows tax credits to be applied on the entire system.

• Viking created a custom assembly process to ensure consistency and quality control across all 42 zone systems. The shipped product is a fully trimmed assembly with grooved fittings and hoses attached, and arrives at the construction site in the cabinet and ready to connect to the water input. Every unit is leak and friction tested before it leaves the factory. Two trained and experienced assemblers are dedicated to the project to ensure each system is identical and in perfect working order.

According to Marn Workman, VP of Product Development for Viking, “This project presented a design and domesticity challenge that we were well equipped to meet. Viking manufactures valves for flow rates anticipated in fire protection systems, and provides a domestic product that meets government specifications. Our Purchasing and Quality departments were able to provide material certifications for all items in the on/off deluge cabinets that satisfied everyone’s requirements. Both National Fire Protection and the Port of Miami were

extremely pleased with the result.”